Commercial Roof Replacement – Poughkeepsie, NY

Location: Poughkeepsie, New York

Property Type: Historical Building

Product Used:

- Single-ply reinforced PVC (Polyvinyl Chloride) roofing membrane

- .050 dark grey PVC roofing membrane

- Roof insulation layers

- Mechanical fasteners and plates

- Stack flashing components

- Rubber pavers

Project Summary

Historical buildings present unique roofing challenges. This Poughkeepsie property faced multiple water intrusion issues that threatened both the structure and daily operations.

The building required a solution that would solve existing problems without compromising its historical integrity. Traditional complete tear-off methods would have been costly and disruptive to the building’s occupants.

Vanguard Roofing implemented a retrofit waterproofing membrane system as the ideal solution. This approach allowed the existing roofing assembly to remain in place, avoiding the substantial capital expenditure associated with complete removal.

The retrofit method provided significant advantages beyond cost savings. There was minimal disruption to daily business operations. The building maintained its structural character while gaining modern waterproofing performance.

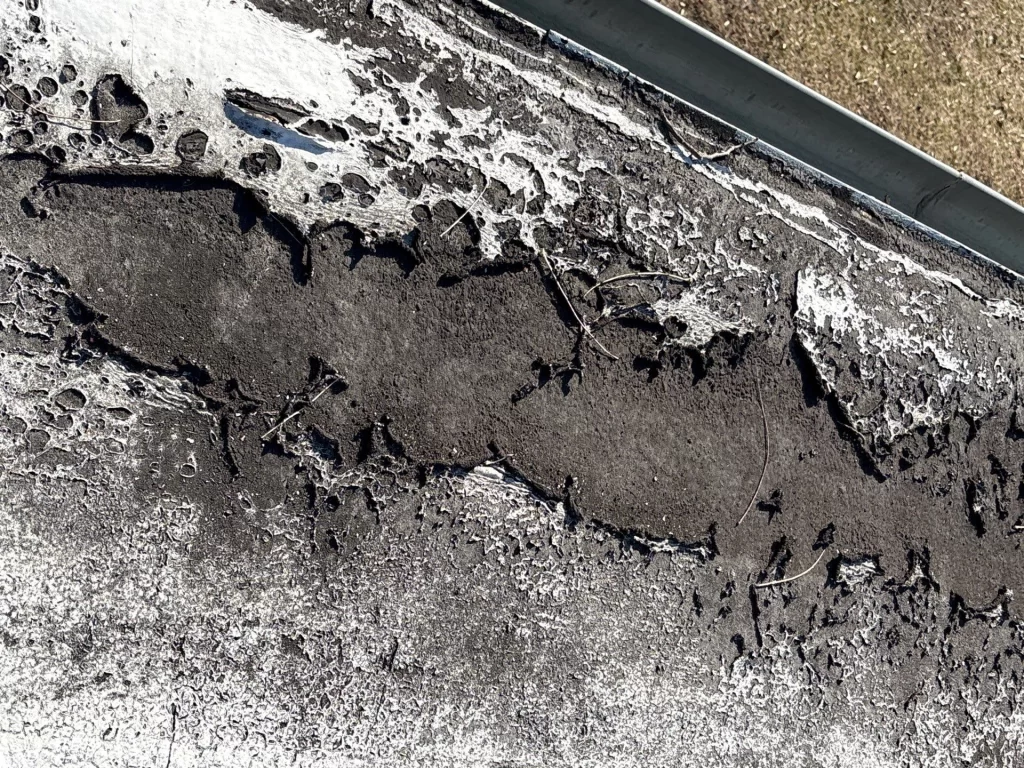

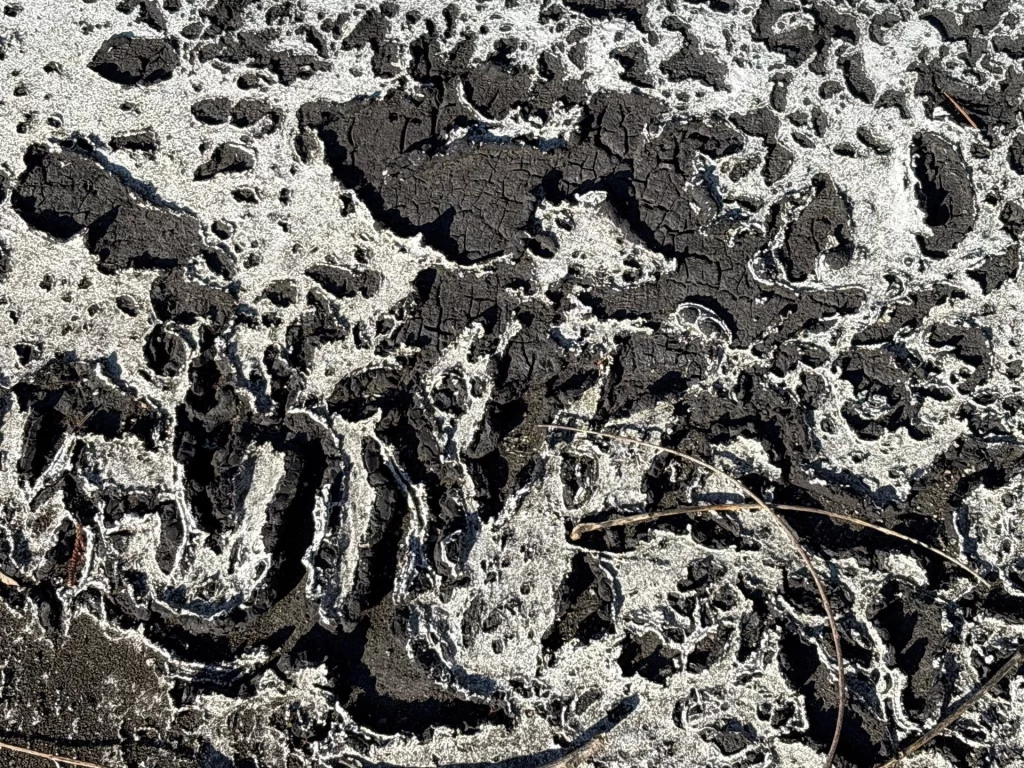

Aged Asphalt Built-Up Roof

The existing asphalt built-up roof system had reached the end of its serviceable life. Years of exposure to weather conditions had taken their toll on the roofing materials.

Seams throughout the roof system showed significant delamination. This separation created vulnerable pathways for water to penetrate into the building envelope.

Ponding water had become a persistent problem across multiple roof areas. Low spots in the roof deck allowed water to collect and sit for extended periods after rain events.

These standing water pools accelerated roof deterioration. The constant moisture exposure compromised the waterproofing integrity and created ideal conditions for leaks to develop.

Solution:

Vanguard Roofing addressed the drainage issues through strategic roof build-up. Multiple layers of insulation were installed to create a positive slope and eliminate low spots.

Custom crickets were fabricated and installed at critical locations. These tapered insulation components redirected water flow toward the existing drain system.

The new roof design eliminated all areas where water could pond. Every section of the roof now features a proper slope to move water efficiently off the surface.

This proactive drainage solution protects the new roofing investment. By preventing water accumulation, the system extends the roof’s service life and prevents future leak issues.

Compromised Flashings

The flashings connecting the lower roof to the upper wall sections had multiple problems. These critical waterproofing components were positioned too low on the building facade.

Over time, the flashings had lost their adhesion to the building surface. Temperature cycling and weather exposure had weakened the bond between flashing and substrate.

Water was finding its way behind the failed flashing terminations. This infiltration traveled down to the lower roof sections, causing interior leaks.

The inadequate flashing height created a fundamental design flaw. Even minor wind-driven rain could force water past these low-positioned barriers.

Solution:

New flashing components were installed at significantly higher elevations. This improved positioning provides better protection against wind-driven rain and water infiltration.

Long-term securement methods replaced the failed adhesive bonds. Termination bars were mechanically fastened through the new waterproofing membrane into the building structure.

The raised flashing profile creates a more substantial barrier against water intrusion. Multiple inches of added height dramatically improve the building’s weather resistance.

All termination points were properly sealed and finished. The installation methods provide decades of reliable performance without the adhesion failures that plagued the original system.

Failing Copper Gutters

The building’s copper gutter system showed visible signs of distress. Sections of the gutters had pulled away from the building and sagged noticeably.

Inadequate support caused the gutters to deform under their own weight. Water and debris accumulation added extra stress to the already compromised system.

The sagging prevented proper water flow toward the downspouts. Water would collect in low spots within the gutter runs, sometimes overflowing during moderate rainfall.

Standing water in the gutters created its own set of problems. The constant moisture exposure accelerated corrosion and allowed debris to accumulate more readily.

Solution:

Vanguard Roofing reinforced the gutter system with added hangers. These support components were strategically positioned to eliminate all sagging sections.

Each gutter run was carefully realigned to restore proper slope. The gutters now maintain a consistent pitch toward their respective downspout connections.

The improved support structure prevents future sagging issues. The copper gutters can now handle water flow and debris loads without deformation.

Proper water management begins with functional gutters. This restoration work protects both the new roof system and the building’s foundation from water damage.

Equipment Area Vulnerability

Mechanical equipment on the roof required regular service and maintenance. HVAC technicians and other service personnel accessed these areas frequently throughout the year.

The high-traffic zones showed significant wear and damage. Dropped tools, foot traffic, and equipment placement had taken their toll on the roofing surface.

Small punctures and abrasions compromised the roof membrane in these locations. Each incident created potential leak points that could worsen over time.

The damage was concentrated around service doors and equipment access points. These were precisely the areas that would continue to see heavy use after the roof replacement.

Solution:

Rubber pavers were installed at all mechanical equipment service doors. These protective walkway systems create a durable barrier between foot traffic and the roof membrane.

The pavers distribute impact forces across a wider area. Dropped tools and equipment no longer come into direct contact with the waterproofing membrane.

Service personnel can work safely without damaging the roof. The pavers provide a stable footing while protecting the roofing investment.

This proactive protection strategy extends the roof’s service life. Areas that previously failed prematurely will now match the longevity of the rest of the system.

Skylight Leaks

Multiple skylights throughout the building had become sources of water infiltration. The original flashing details had failed to maintain weathertight seals.

Poor flashing design allowed water to bypass the skylight curbs. Rain and melting snow found pathways through gaps and deteriorated sealant.

Interior damage from skylight leaks affected occupied spaces below. Ceiling stains and water damage created aesthetic problems and raised concerns about structural issues.

The skylight leak problems required more than simple resealing. The entire flashing approach needed to be redesigned and properly installed.

Solution:

Stack flashing was installed around every skylight unit. This multi-layer flashing approach creates redundant waterproofing barriers.

Outside corners received special attention with custom-fabricated components. These vulnerable transition points now feature proper material overlaps and weatherproofing details.

All caulking and sealant was carefully tooled into place. Proper application technique creates better seals and produces a neater, more professional appearance.

The complete skylight waterproofing eliminates all previous leak sources. Each unit now features proper flashing integration with the new roof membrane system.

Process

Safety Setup: Perimeter warning lines were established in compliance with OSHA recommendations throughout the roof work area. Ground-level zones, including dumpster locations, temporary storage, tools, equipment, and materials, were cordoned off with warning lines and temporary stanchions.

Surface Preparation: All breaks, splits, ruptures, and weak spots in the existing roofing were reinforced to create a stable base for the new waterproofing installation.

Insulation Installation: Multiple layers of insulation were installed in a staggered pattern using mechanical fasteners and plates to build up the roof and create positive drainage.

Membrane Application: A reinforced .050 dark grey PVC roofing membrane was fully adhered over the insulation, then heat-welded membrane-to-membrane to create a monolithic roof system with no weak points.

Detail Work: Custom flashing, gutter adjustments, and protective paver installation completed the waterproofing system.

Project Highlights

- Retrofit approach eliminated costly tear-off expenses

- Minimal disruption to daily building operations

- Heat-welded monolithic membrane system

- Positive drainage design prevents future ponding

- Enhanced protection at high-traffic equipment areas

- Historical building preservation is maintained

Results & Benefits

The historical building now features a durable, watertight roofing system that addresses all previous leak sources. The retrofit approach saved substantial costs compared to complete roof replacement while delivering superior waterproofing performance. Improved drainage design prevents water accumulation, and strategic protection measures at equipment areas extend the roof’s service life. The building maintains its historical character while gaining modern roofing reliability.

Project Gallery

Key Specifications

- Membrane Type: Fully adhered PVC

- Membrane Thickness: .050

- Membrane Color: Dark grey

- Installation Method: Heat-welded seams

- Insulation: Multi-layer, staggered installation

- Fastening System: Mechanical fasteners with plates

- Drainage Enhancement: Custom crickets and positive slope design

- Safety Compliance: OSHA-compliant perimeter protection

Special Features

- Retrofit installation over the existing roof assembly

- Custom drainage solutions with built-up insulation and crickets

- Enhanced flashing system with elevated termination points

- Rubber paver protection at mechanical equipment locations

- Restored and realigned the copper gutter system

- Professional skylight waterproofing with stack flashing

Is Your Historical Building in Need of Professional Roofing?

At Vanguard Roofing, we specialize in historical roof replacements and flat roof restorations for Poughkeepsie and the Hudson Valley region. Our expertise in retrofit roofing solutions delivers superior results while respecting your building’s character and history.

Contact Vanguard Roofing today to discuss your commercial roofing needs. Schedule a free roof inspection and quote to learn how we can protect your building investment.